You’ve spent months building a state-of-the-art hyperscale data center. Your team executed flawlessly. MEP installations are complete. The facility looks ready. Your hyperscaler client is expecting turnover soon.

Then commissioning starts. And everything falls apart.

Systems that should integrate smoothly don’t talk to each other. Documentation that should be complete has critical gaps. Performance tests that should pass reveal cascading failures. The finish line that seemed so close keeps moving further away.

Welcome to the final mile, where more hyperscale projects fail than during any other construction phase.

It’s like training for a marathon for months, running 26 miles perfectly, then collapsing 100 yards from the finish line. You did all the hard work, but you don’t get credit for finishing.

What Makes Commissioning Different

(and Dangerous)

Industry data shows that 65% of major hyperscale project delays occur not during primary construction, but in the gaps between trades during critical handoff points. Commissioning represents the ultimate handoff, where everything you built has to prove it actually works together as a complete, integrated system.

During construction, trades work largely independently. Electrical installs their systems. Mechanical installs theirs. Plumbing, fire protection, controls, each doing their piece. Problems stay contained within individual trades.

But commissioning is different. Everything has to work together:

- Power systems must integrate with cooling systems

- Building management systems must communicate with all mechanical equipment

- Fire suppression must coordinate with electrical shutoffs

- Backup generators must seamlessly take over during power failures

- Monitoring systems must accurately report status across all systems

One gap in any of these integrations, and the entire system fails validation. And hyperscalers don’t accept partial completion.

Think of it like an orchestra. During rehearsal, each section practices separately. The strings sound great. The brass sounds great. But the first time everyone plays together? That’s when you discover the violins are in a different key than the trumpets. Commissioning is your first full orchestra rehearsal, and there’s no time for a do-over.

The Three Fatal Gaps That Derail Commissioning

Based on analysis of hyperscale project failures, commissioning problems trace back to three coordination gaps that develop during construction but don’t become visible until testing begins:

Gap 1: Documentation Gaps

Commissioning requires complete, accurate documentation of every system. As-built drawings, equipment specifications, programming parameters, testing procedures, and maintenance protocols must all be current and accurate.

The problem? Documentation is typically treated as paperwork to catch up on later, not as a construction deliverable that must stay current throughout the project.

When commissioning starts, teams discover:

- As-built drawings don’t reflect field changes made during construction

- Equipment submittals are missing or incomplete

- Control system programming isn’t documented

- Testing procedures reference equipment that was swapped out months ago

- Operations manuals don’t exist yet

Commissioning agents can’t verify systems without accurate documentation of what was actually built. Testing stops. Teams scramble to recreate documentation. Critical time vanishes.

It’s like trying to follow a recipe where half the ingredients are crossed out and replaced with handwritten notes you can’t read. You might eventually figure it out, but not before burning several batches.

Gap 2: System Integration Issues

Hyperscale data centers have incredibly complex system integration requirements. Building management systems must communicate with hundreds of pieces of equipment. Power monitoring must integrate with cooling control. Fire systems must coordinate with electrical systems.

The problem? Integration planning typically happens too late, after equipment is already installed and programmed.

During construction, each trade installs their systems according to spec. Electrical puts in their monitoring. Mechanical installs theirs. Controls does their programming. Everything works independently.

Then commissioning starts and teams discover:

- Communication protocols don’t match between systems

- Data points aren’t mapped correctly in the building management system

- Alarm sequences don’t trigger properly across systems

- Equipment installed months ago needs firmware updates to work with newer systems

- Network architecture doesn’t support the required data flow

Fixing these issues requires reprogramming, reconfiguring, sometimes even replacing equipment. What should have taken days becomes weeks or months of troubleshooting.

Imagine building a house where the electrician and plumber never talked. The lights work. The water works. But when you try to install the dishwasher, you discover the electrical outlet is on the opposite wall from the water connection. Everything has to be redone.

Gap 3: Performance Verification Delays

Even with complete documentation and working integration, commissioning can still fail during performance verification, when systems must prove they meet design specifications under various operating conditions.

The problem? Performance testing reveals problems that should have been caught during installation or startup.

Common performance failures include:

- Cooling systems can’t maintain required temperatures under full load

- Power distribution doesn’t deliver rated capacity

- Backup generators don’t seamlessly transfer load during simulated failures

- Air handlers create pressure imbalances that affect other zones

- Control sequences don’t respond properly to varying conditions

Each failed test requires investigation, correction, and retesting. One failure cascades into another. Testing timelines extend significantly.

It’s like doing a dress rehearsal the night before opening night and discovering the lead actor can’t remember their lines. Sure, you can fix it, but not without delaying the premiere.

The Real Cost of Final Mile Failures

Commissioning delays aren’t just schedule problems. They’re existential threats to project success and future business opportunities.

Direct Delay Costs

Every day of commissioning delay costs money. Extended general conditions, retained subcontractors, project management overhead. For hyperscale projects, industry estimates suggest daily delay costs can escalate into hundreds of thousands of dollars for large facilities.

Liquidated Damages

Most hyperscale contracts include substantial liquidated damages for late delivery. Extended delays can trigger significant penalties that compound the financial impact of schedule overruns.

Lost Revenue Opportunity

For hyperscalers, every day a data center sits empty is lost revenue opportunity. They’re not just paying late delivery penalties, they’re losing the income that facility was supposed to generate. That relationship damage extends beyond the current project.

Preferred Vendor Status at Risk

Hyperscalers track contractor performance religiously. Commissioning delays affect your preferred vendor status for future projects. One final mile failure can cost you multiple future opportunities worth hundreds of millions.

Reputation Damage

In the tight knit hyperscale construction market, word travels fast. Contractors known for commissioning problems find it harder to win competitive bids. Your track record becomes your calling card, good or bad.

The paradox? The cost to prevent commissioning failures is a fraction of the cost to fix them after they happen. But prevention requires changing how you approach the entire project, not just the final phase.

Why Traditional Approaches Fail

Most contractors approach commissioning the traditional way: hire a commissioning agent late in the project and hope for the best. This approach treats commissioning as an end-of-project activity rather than an integrated process.

This approach fails because commissioning isn't an activity that starts near the end of construction. It's a process that must be integrated from project start.

When you bring commissioning agents in late:

- They inherit documentation gaps they can’t fix

- They discover integration issues after systems are fully installed

- They find performance problems that require major rework

- They lack relationships with trade contractors who have already demobilized

- They have no leverage to enforce documentation requirements

It’s like hiring a wedding planner the week before the wedding. Sure, they’re experts, but they can’t fix problems that were baked in months ago. They can only help you manage the chaos.

The contractors who consistently deliver successful commissioning do something fundamentally different. They embed commissioning thinking into the entire project lifecycle.

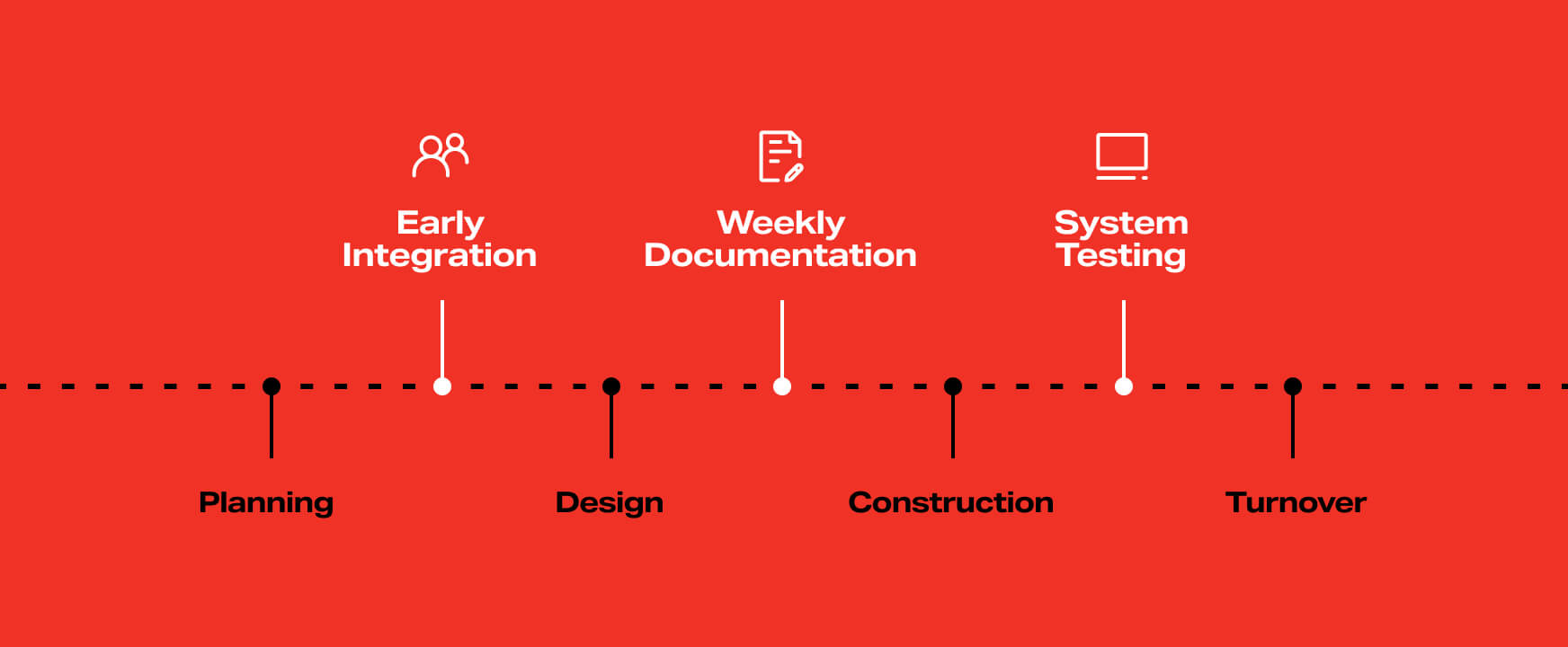

Commissioning Readiness: The Preventive Approach

Instead of treating commissioning as a final phase, leading contractors build commissioning readiness into their entire project execution strategy:

1. Early Commissioning Integration

Engage commissioning specialists during design and preconstruction. Early involvement allows them to:

- Review design documents for testability and integration requirements

- Establish documentation standards before construction starts

- Develop testing procedures that align with installation sequences

- Identify potential integration issues while there’s time to redesign

- Build commissioning requirements into subcontract scopes of work

Think of it like having an editor review your book outline before you start writing, instead of handing them 500 pages and saying fix it. Prevention beats correction every time.

2. Continuous Documentation Discipline

Make documentation a weekly deliverable, not an end-of-project scramble. Implement systems that:

- Require as-built updates within days of field changes

- Track documentation completion as rigorously as construction progress

- Link payment releases to documentation deliverables

- Use digital tools that make documentation capture easy

- Conduct regular documentation audits to catch gaps early

When documentation stays current, commissioning agents can verify work as it happens instead of trying to recreate it months later.

3. Progressive System Testing

Don’t wait until everything is installed to start testing. Use a phased approach:

- Functional testing as systems come online

- Integration testing as soon as connected systems are operational

- Performance testing on a rolling basis by zone or system

- Early identification of problems while trades are still on site

- Shorter, more focused testing cycles instead of one massive final push

Progressive testing spreads the commissioning workload across the project timeline instead of cramming everything into the final phase. Problems get fixed when they’re small and manageable, not when they’re critical path blockers.

4. Integrated Coordination

The most effective approach integrates commissioning coordination with safety, logistics, and construction scheduling. Commissioning specialists who understand MEP sequencing and safety protocols can coordinate testing with safety protocols and logistics planning.

When your team understands that:

- Documentation quality affects commissioning timeline

- Integration planning must happen before installation

- Testing sequences drive construction sequencing

- Commissioning readiness is everyone’s responsibility, not just the commissioning agent’s

Then commissioning becomes a coordinated process instead of a chaotic sprint at the finish line.

Real Results: When Commissioning Readiness Works

A hydrogen production project with 195 employees across two locations demonstrates what embedded commissioning coordination can achieve. By integrating Process Safety Management protocols with workforce coordination from project start:

Zero recordables on one project

Only 1 recordable out of 120 employees on another project

Projects completed ahead of schedule

Smooth commissioning with no major delays or rework

The difference? Commissioning readiness was built into the project from day one, not bolted on at the end.

Similarly, an OnPoint client achieved a 73% reduction in OSHA recordable cases, 47% reduction in lost-time incidents, and 46% reduction in DART rates through integrated safety management that included proactive commissioning coordination across all operational functions.

Is Your Project Ready for Commissioning?

Use this quick assessment to evaluate your commissioning readiness:

Documentation Readiness:

- Are as-built drawings current?

- Do you have complete equipment submittals for all installed systems?

- Are control system programs documented and backed up?

- Have operations and maintenance manuals been started?

Integration Planning:

- Have system integration requirements been mapped?

- Are communication protocols verified between systems?

- Has control system programming been tested for cross-system coordination?

- Do you have a clear integration testing schedule?

Testing Preparation:

- Are functional test procedures written and approved?

- Have performance test parameters been defined?

- Is testing sequencing coordinated with construction milestones?

- Do you have adequate time allocated for retesting if needed?

If you answered ‘no’ to more than three questions, your project has commissioning readiness gaps that need immediate attention.

Our Hyperscale Risk Assessment Toolkit includes a comprehensive Commissioning Readiness Scorecard that evaluates your project across:

- Systems Integration (30%): Cross-system coordination and communication readiness

- Documentation Completeness (25%): As-builts, submittals, and O&M manual status

- Performance Verification (25%): Testing procedures and validation readiness

- Operational Handoff Preparation (20%): Training, documentation, and facility management transition

Get your commissioning readiness score in minutes.

Access the Free Hyperscale Risk Assessment ToolkitThe Bottom Line

Commissioning failures don’t happen during commissioning. They happen during design and construction when nobody’s thinking about commissioning yet.

The contractors who consistently deliver successful turnovers don’t have better commissioning agents. They have better commissioning integration throughout the entire project lifecycle.

Documentation discipline. Integration planning. Progressive testing. Cross-functional coordination. These aren’t nice-to-haves. They’re the difference between finishing your project successfully and collapsing 100 yards from the finish line.

Your hyperscale client doesn’t care that you built 99% of a perfect facility. They care about the 1% that keeps them from going operational.

Don’t let the final mile be where your project fails.

About OnPoint

OnPoint delivers comprehensive embedded execution support for hyperscale AI and cloud data center construction. Our cross-trained specialists integrate safety, logistics, transportation, and commissioning coordination to help contractors eliminate costly handoff failures and deliver predictable results on complex projects.